- Learn from the Living Library

Recipe for Agar Bioplastics

GENERAL INFORMATION

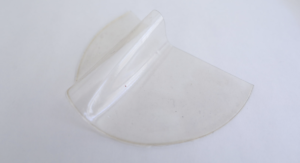

Agar (also called agar-agar) is a polymer of agarose (a kind of sugar). It is a substance obtained from red algae. Agar has been used as a gelling and thickening agent in desserts throughout Asia and also in microbiology to obtain a solid medium. Agar can also be used as a vegan substitute for gelatin (made from animals). Agar bioplastic is made by mixing water, glycerine and agar powder. Together they form a foil-like plastic substitute that is flexible, but not elastic.

RECIPE

INGREDIENTS FOR 500 mL OF BASIC AGAR BIOPLASTIC FOIL

- Agar agar 10g

- the polymer to make the structure

- Glycerine 30g

- The plasticizer to make it flexible

- Water 500 mL

- The solvent to dissolve the materials

- Essential oil 2 drops

- Anti-bacterial to keep it from contaminating

TOOLS

- Pan (non-reactive)

- Cooking plate

- Scale with 1g precision

- Thermometer

- Spoon

- Whisk

- Optional: Textiles, molds or casting surfaces

- Optional: Pigments, food colorants or natural dyes

- Optional: Fillers of your choice (eggshell powder, coffee debris, chalk, fibers, …)

METHOD

- Warm up the water in the pan on the cooking plate to a max of 80ºC (hot, but not boiling).

- Optional: If you want to dye your material in one colour, supplement part of the water with natural dye (if concentrated only a few drops).

- Add the glycerin and a few drops of essential oil to the water.

- The general rule is the more glycerine, the more flexible the material.

- Too much glycerine will make the material too sticky.

- Add the agar to the mixture.

- Add slowly and evenly, while stirring gently will help it dissolve better.

- Whisk gently until the ingredients form a smooth mix.

- Don’t over-whisk it to avoid the creation of bubbles.

- Simmer for about 30 minutes while stirring regularly.

- The mixture should be syrupy rather than watery before casting.

- Optional #1: Add a filler and mix gently until it is evenly distributed throughout the liquid.

- Optional #2: If you are planning to make a batch of different colours, prepare your colours in a small container, to which you will add the liquid when it is ready to cast.

- Pour the mixture into your mold or on your chosen surface.

- Pour slowly to avoid air bubbles

- Let dry for about a week.

- the temperature and humidity will influence the drying time and shrinking

REFERENCES