- Learn from the Living Library

Recipe for Alginate

GENERAL INFORMATION

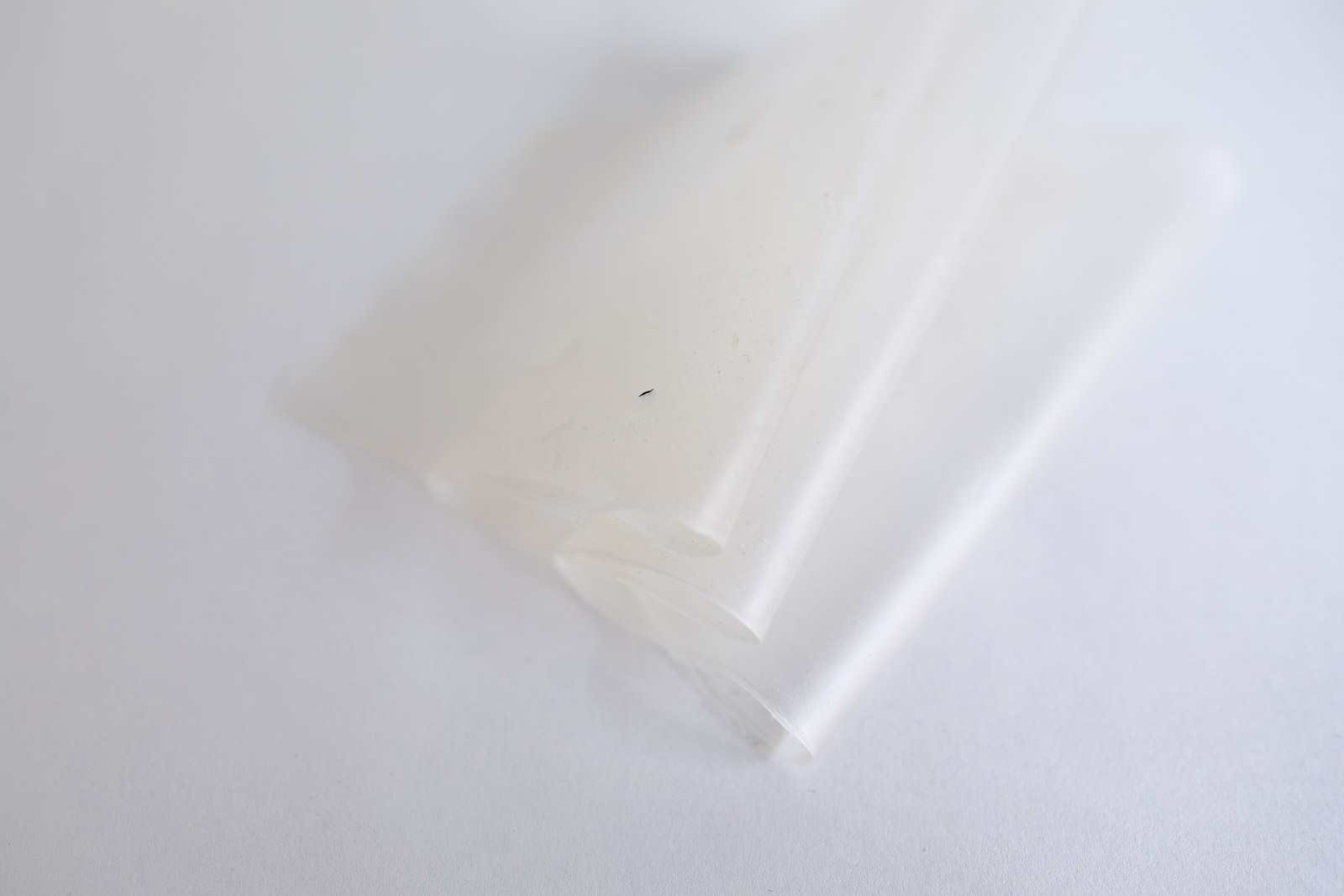

An alginate based, heat-resistant and waterproof semi-transparent, matte foil. The foil has a feel that can be compared with a window foil (to blind windows but let the light through). It’s matte but very translucent. It doesn’t crackle or jump back like a lot of other foils.

This entry is based on the work of Loes Bogers for the 2020 Textile Academy at the Waag

RECIPE

Ingredients for 400ml alginate

- Sodium alginate powder – 12 gr

- the polymer (so it becomes a solid)

- Glycerine – 20 gr

- the plasticizer that bonds with the alginate (makes it flexible).

- Water – 400 ml

- to dissolve and mix the polymer and plasticizer

- optional: use a (diluted) natural dye instead for a colored plastic

- Sunflower oil – 10 gr

- filler to reduce shrinkage

- Calcium chloride solution 10% (10 gr/100 ml water to spray onto the alginate)

- is the curing agent: calcium chloride attracts moisture very strongly. Spraying it onto the alginate plastic starts the curing process.

Tools

- Scale

- Spoon

- Blender

- Glass jar with lid

- Spray bottle (150 ml contents, for the calcium chloride solution)

- Acrylic sheet smooth surface to cast the foil onto. A smooth surface will create a smooth matte foil.

- A strip of acrylic or squeeguee to push the alginate mixture into place and form an even and flat rectangle

- Painting tape to tape down if the edges of the sheet start to come off of the surface

- Kitchen paper to soak up the water that will be released from the alginate mixture

Method

- Preparation

- Weigh your ingredients for the alginate plastic (alginate, glycerine, water, sunflower oil). Optional: use a diluted natural dye instead of water in the same amount for a colored plastic.

- Put the oil, alginate and glycerine in a blender and add a dash of water. Blend into a thick and homogenous paste. Then add the rest of the water and blend again (this is to avoid lumps).

- Leave the mixture overnight to allow the bubbles to come to the surface and pop.

- Make the calcium chloride solution by dissolving 10 gr in 100 gr hot water. Put it in a spray bottle.

- Casting

- Prepare some space on an acrylic or glass surface

- Pour the alginate onto the acrylic sheet and use the acrylic strip to mold the liquid into a rectangular shape of about 3mm high

- Spray the sheet with the calcium chloride solution (use quite a lot)

- Let it sit for a few minutes, then spray again if you see the liquid is starting to ooze out from the sides. The film that is created in the curing process can break from the weight of the liquid bubble. By respraying, you can close these until the sheet is cured enough and stable to dry further.

- The alginate can release quite a lot of water at this stage, so it’s wise to place some kitchen paper around it to absorb excess water.

Shrinkage and deformation control

Keep an eye on the sheet every few hours, especially on the first day. The thinner edges of the sheet might curl up when drying and pulling off parts of the sheet. When it comes off it will start to warp. Taping it down onto the acrylic helps to keep it in place a dry in shape. Let it dry for up to seven days to get to the final form. When it no longer feels cool to the touch it is dry enough to take off. If you want to trim the edges do it while the foil is still a bit softer for a clean cut.

REFERENCES

- Flexible Bio-plastic Alginate Recipe by Cecilia Raspanti (TextileLab, Waag), Fabricademy Class “Biofabricating Materials”, 2019, link.

- Alginate Recipe by Catherine Euale, Fabricademy 2018-19 link

- The Science Of Spherification: Theoreticians examine the atomic details of an avant-garde culinary technique”, by Bethany Halford, Chemical and Engineering News, Volume 92 Issue 42, pp. 35-36, October 2014: link

- Alginic Acid on Wikipedia: link

- Development of bio-plastic from production technologies from microalgae by AlgaePARC for Wageningen University & Research, 2012-2016: link

- Recipes for Material Activism by Miriam Ribul, 2014, via issuu link

- Research Book Bioplastics by Juliette Pepin, 2014, via issuu link